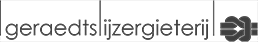

Molding line

– Jobbing foundry, with furan sand

– 7 jobbing stations, each with own facilities for core production

– Coatingstation for each jobbing station

– Maximal mould dimensions: 7.000×3.500x2000mm

– Maximal cast weight: 16.000kg

Melting furnaces

– Two medium frequency coreless induction furnaces

– Maximum capacity: 3,500 Kg per furnace

– Melting capacity: 3,000 Kg per hour

– Maximum of 30,000 Kg of liquid metal per day

Pouring

– Ladle capacity: max 8.000kg

– Treatment for the production of grey and ductile irons

– Inoculation in ladle and in-stream

– Maximum cast weight: 16,000 Kg

Finishing

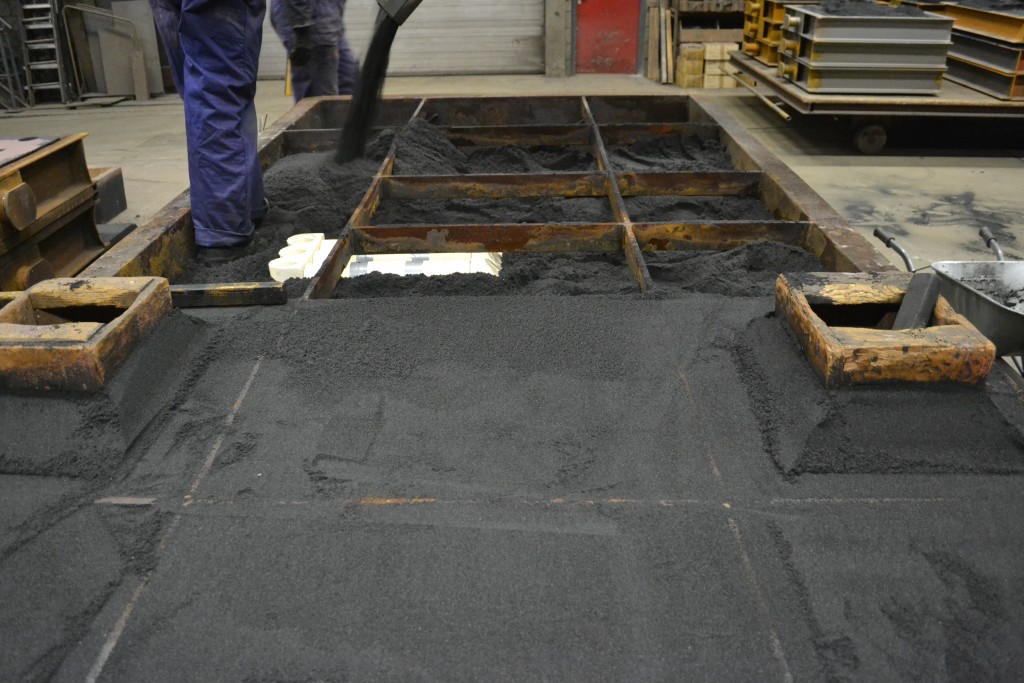

– Removing sand mold

– Shot blasting

– Deburring and grinding

– Machining (on request)

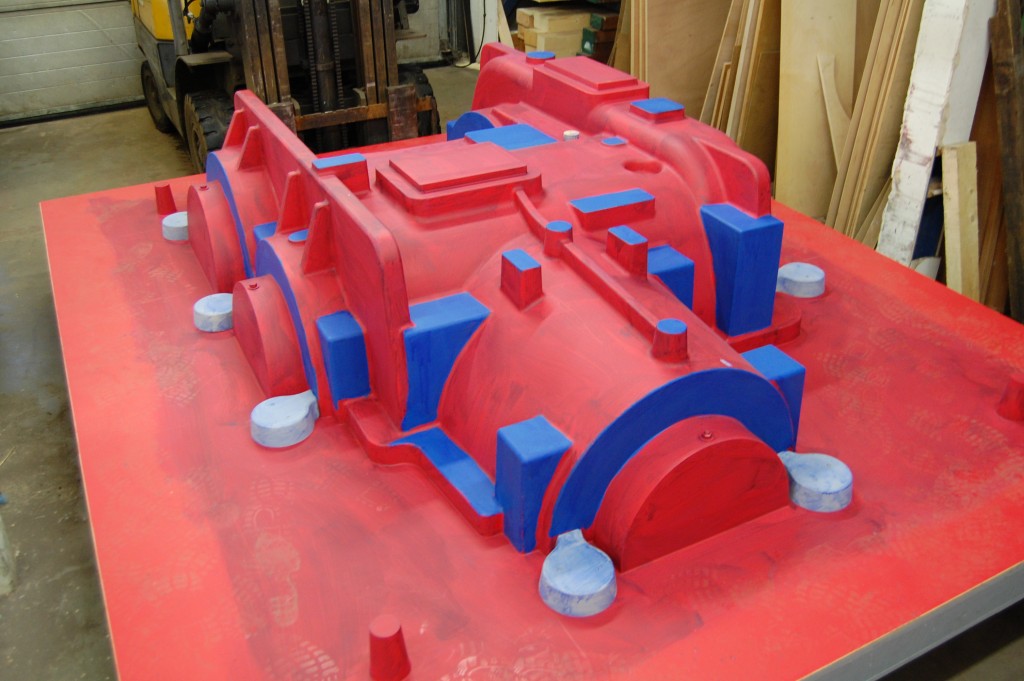

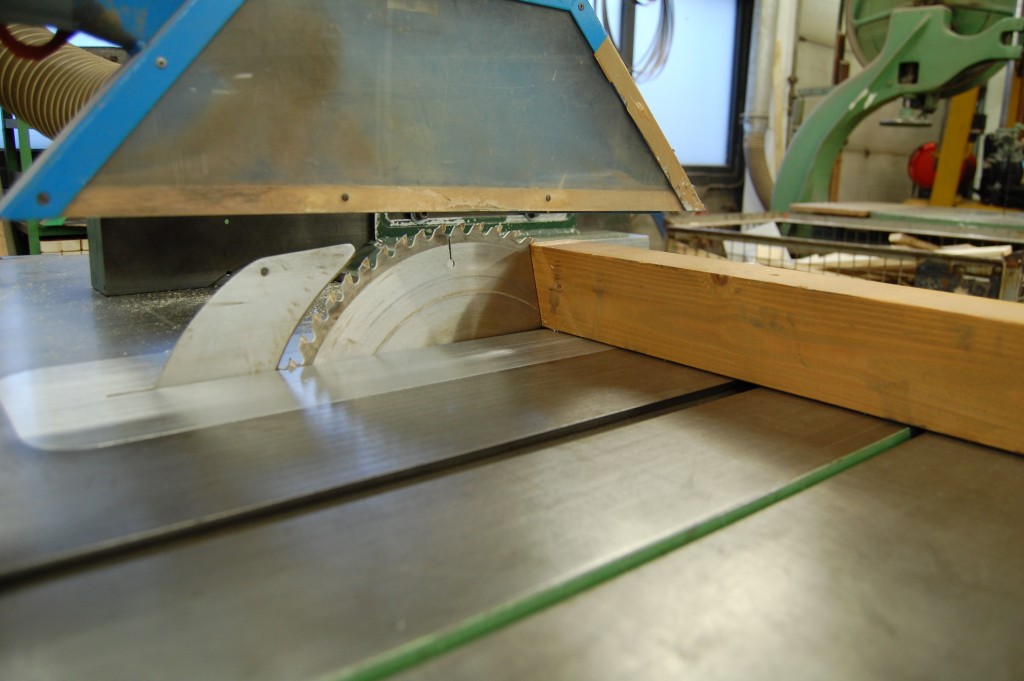

Pattern shop

-Construction of new patterns

-Modifications

-Repairs

-Storage of patterns for our customers

-Over 10,000 patterns in storage